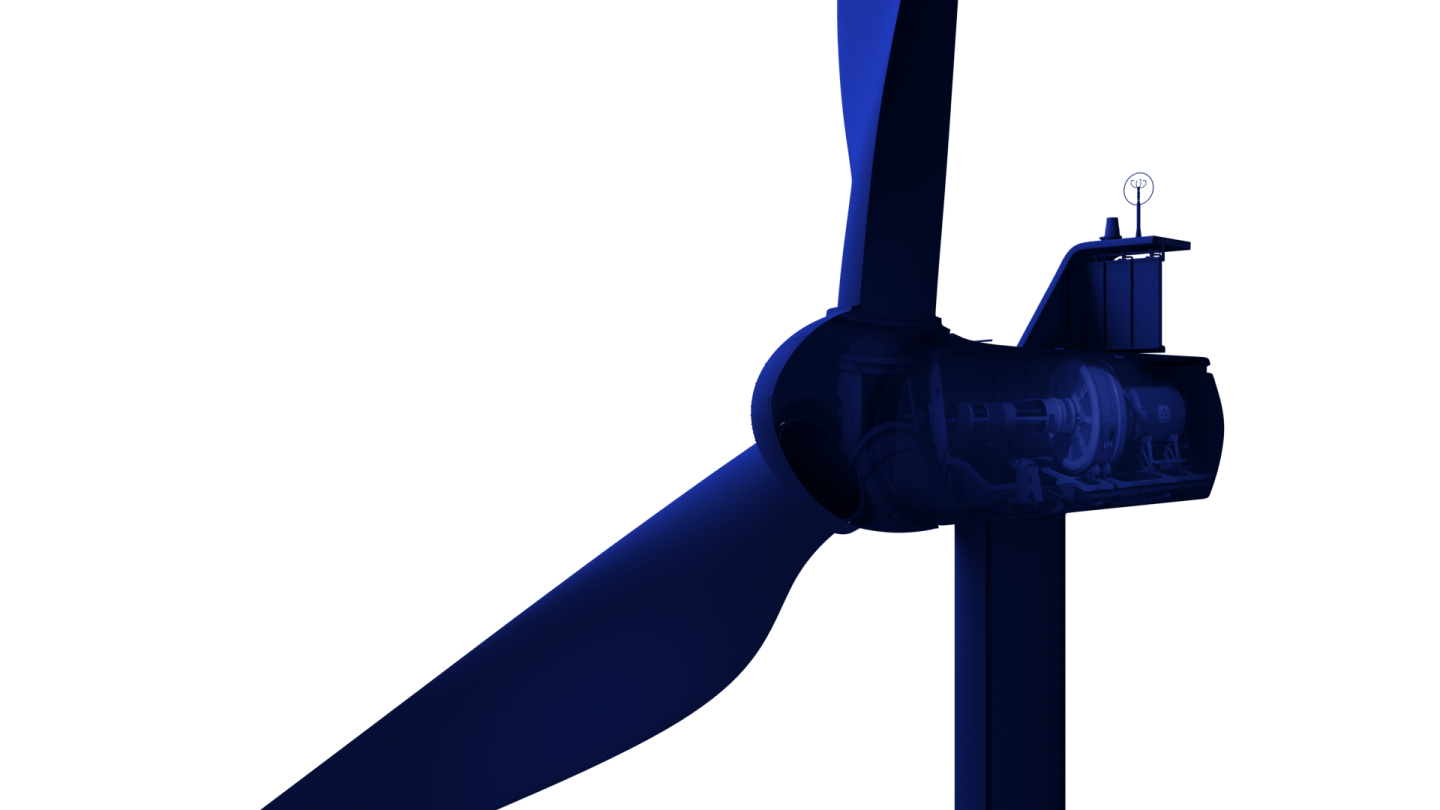

Optimum control of the blade pitch angle is important on all modern wind turbines, making the pitch system an integral part of the wind turbine. The pitch system not only ensures the pitch angle for optimum power control, but simultaneously works as the primary safety system on the turbine – thereby protecting it from overly strong winds. Our pitch systems consequently increase overall performance as well as the life cycle of the wind turbine.

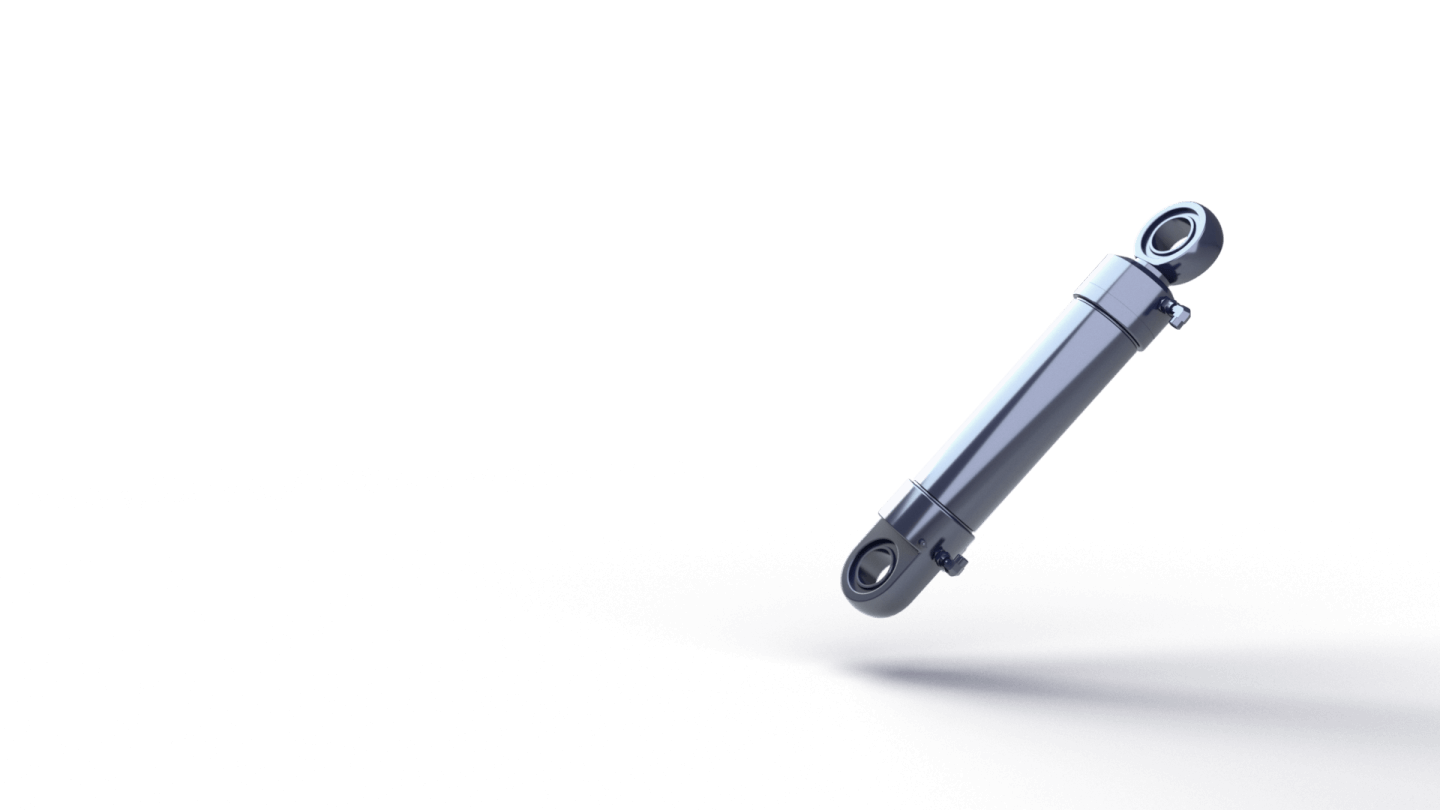

The pitch actuator is the heart of the hydraulic pitch system, transforming the demand signal from the turbine controller into the right pitch angle. Different combinations of pitch actuators are possible – we can supply both one and two pitch actuators per blade. Using our proprietary software, we design the right sealing system to ensure long-lasting and reliable performance.

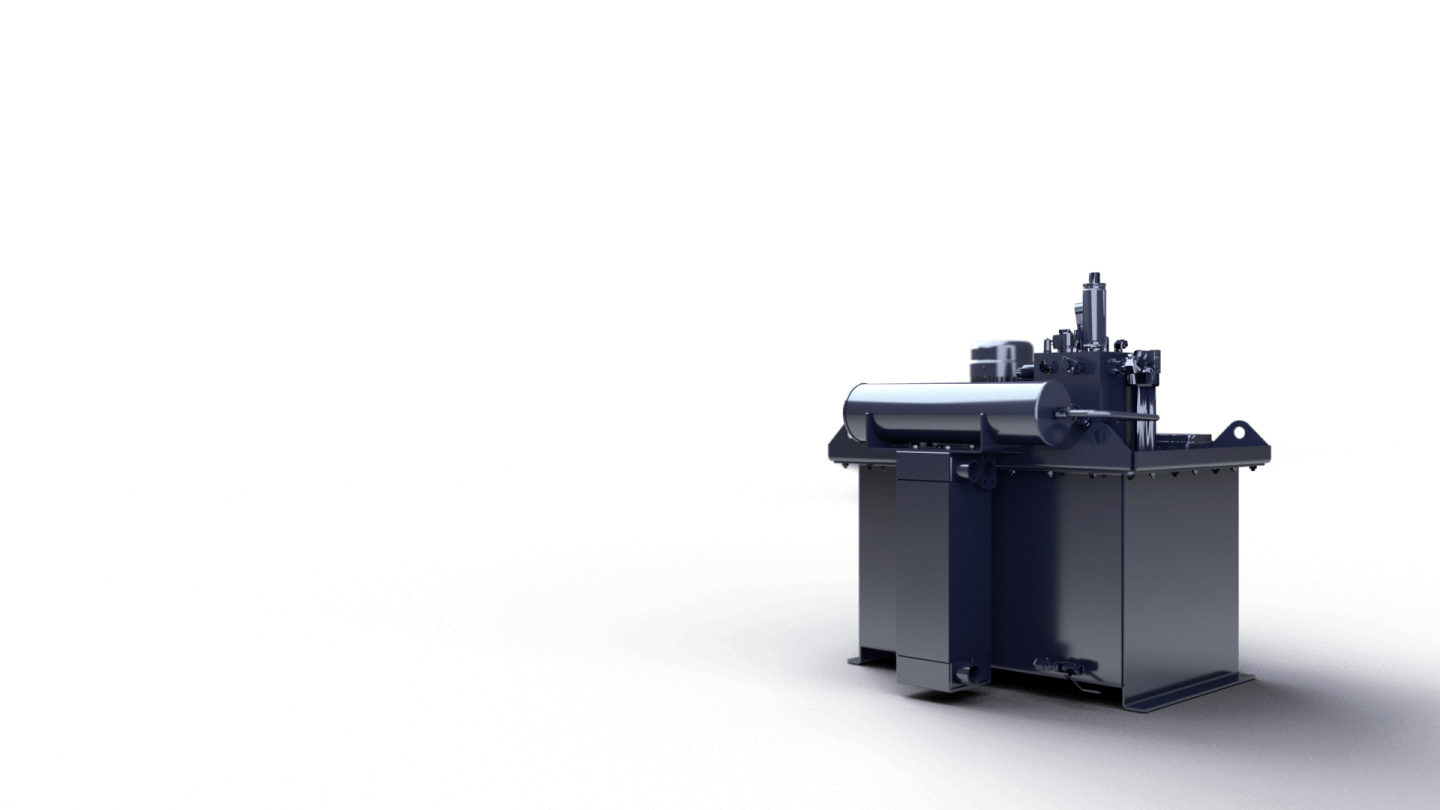

The power pack (HPU) contains the oil reservoir and can take different forms. At Ymer Technology, we don’t just match your specifications, we also focus on creating a solution that is easy to service. Furthermore, the power pack can also handle auxiliary functions such as the control of yaw brakes, high-speed shaft brakes and the inboard crane. Our customized pitch power packs are easily integrated into the nacelle infrastructure. We include a cooling solution for the oil, ensuring an easy interface and optimized design resulting in minimal use of oil.

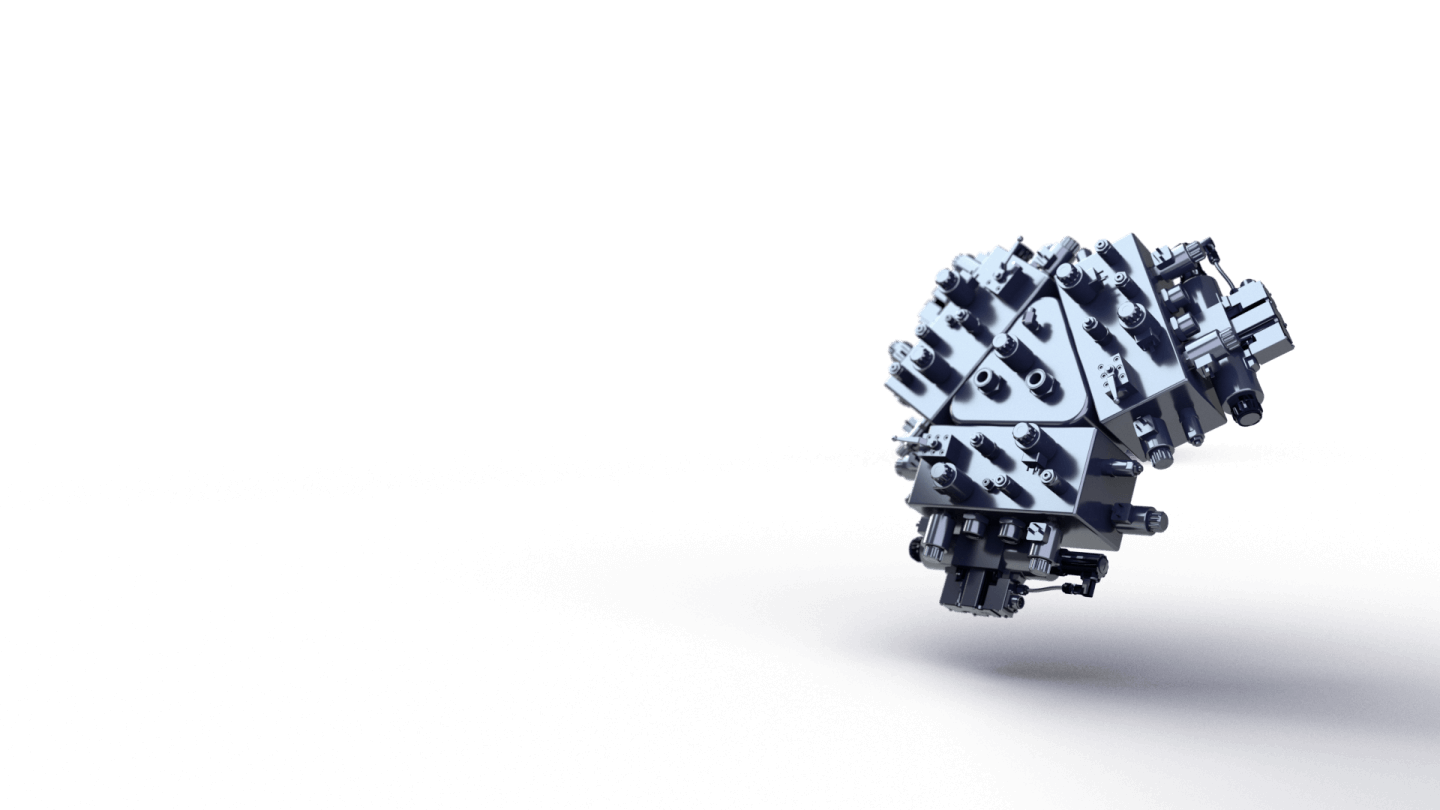

The pitch manifold can have numerous different designs and functionalities, and can be installed as a central unit or on each of the pitch actuators. Our manifolds perfectly distribute oil to each of the blades, ensuring the movement of the pitch actuators while also including the safety circuit of the turbine. We tailor the manifolds to perfectly match the application, while focusing on reducing complexity.

Our pitch systems are designed for superior turbine performance by integrating all components into a compact and effective design. We can include the electric pitch controller, thereby supplying a “plug and play” system that is both simple and, flexible. This gives you the highest possible reliability while leaving you the option of setting the desired blade position. In short: your pitch demand is in safe hands.

Ymer Technology’s wind division that develops and manufactures cooling systems for on- and off- shore wind turbines has been acquired by the Power and Motion company, HydraSpecma. With the transaction HydraSpecma strengthen its position as leading supplier within the wind industry.

With the acquisition of Ymer Technology’s wind division, the international Power & Motion company HydraSpecma headquartered in Skjern, Denmark is becoming an even stronger supplier and development partner to the wind industry. The two companies have recently settled an agreement which will increase strength and capacity to accept even more projects within the wind power segment.

HydraSpecma, that is owned by the Danish industrial conglomerate Schouw & Co, has acquired Ymer Technology’s wind division that is headquartered in Silkeborg, Denmark. HydraSpecma sees a great potential in the wind industry the upcoming years and the two companies will complement each other in multiple areas. HydraSpecma is specialized in lubrication- and filtration systems and pitch-hydraulic, while Ymer Technology have cooling and conditioning of nacelles as their primary business area.

The goal, to achieve an even stronger position in the market has also played a significant role for Ymer Technology Jørgen Krogh, Vice President of Ymer Technology explains. In few years, Ymer Technology has established a robust customer portfolio due to the company’s expertise, especially within cooling systems for wind turbines.

– Through a close cooperation with our customers we have taken significant steps within development. We have gone from being a component supplier to co-developer of systems to some of the largest OEM customers. Now the time has come to take the next large step. The winds of change are blowing within the wind industry and to stand even stronger in that process I see Ymer Technology and HydraSpecma as the perfect match, says Jørgen Krogh.

HydraSpecma have been collaborating with the leading wind turbine manufactures in more than 40 years and are experiencing and increasing demand with the wind power segment. The acquisition of Ymer Technology’s wind division is a prolongation of HydraSpecma’s strategic ambition to strengthen their position with the growing industry.

– HydraSpecma and Ymer Technology is similar in many areas. Both companies excel in service excellence and they both have a flexible production on a global scale, which makes us a strong business partner. Together, we are ready to secure our customers the best complete solutions all the way from prototype development to serial production. We are convinced that this acquisition will make us stronger in this area in the future – Morten Kjær, CEO of HydraSpecma

During the discussions on HydraSpecma’s acquisition of Ymer Technology’s wind division, both Morten Kjær and Jørgen Krogh have been confirmed in the fact that the companies’ values are very close to each other. That has strengthened the belief that the acquisition and increased focus on the wind power industry will become a success.

The acquisition must also be seen in light of the increasing need in the market for consolidation.

– There is no doubt that size matter as a supplier to the wind industry. Our purchase volume and production capacity will increase, and we will stand stronger as we gain strength and capacity to take more projects from all customers and deliver complete systems. Morten Kjær emphasizes and adds that the acquisition will increase HydraSpecma’s revenue with approximately 575m Danish kroner.

HydraSpecma will be the continuing company and will continue to be headquartered in Denmark. HydraSpecma Group and Ymer Technology’s wind division respectively employs 1.300 and 180 persons and have production facilities in Asia, Europe as well as in North- and South America.

Ymer Technology was founded in Sweden in 2005 under the name Ymer Technology AB. Ymer Technology has specialized in cooling systems and thermal management systems. The company is headquartered in Stockholm and has production facilities in Sweden, China, India and USA. In 2021 Ymer Technology had a revenue of 1bn Swedish kroner and the company has 277 employees.

HydraSpecma was founded in 1974 and today it is Denmark’s largest supplier of Power & Motion systems as well as solutions for the wind power industry. HydraSpecma is a customer driven company that delivers advanced hydraulic and electronic solutions for a wide range of segments within the Power & Motion market on a global scale as well as in the local Nordic aftermarket.

HydraSpecma’s wind division also delivers filtration- and lubrication systems as well as pitch-hydraulic systems for the wind industry. HydraSpecma is headquartered in Denmark and have production facilities in Denmark, Sweden, Norway, Finland, Poland, England, Netherlands, India, China and Brazil. HydraSpecma also operates a series of stores for the aftermarket in the Nordics. In 2021 HydraSpecma had a revenue of 2,3bn Danish kroner and the company have 1.300 employees whereof a large part is employed in Denmark and Sweden. Since 1988 HydraSpecma has been a part of the Danish industrial conglomerate Schouw & Co.

For further information please contact:

Vice President, Jørgen Krogh, Ymer Technology, +45 2042 2838

Read more here: https://www.hydraspecma.com/store/dk/en